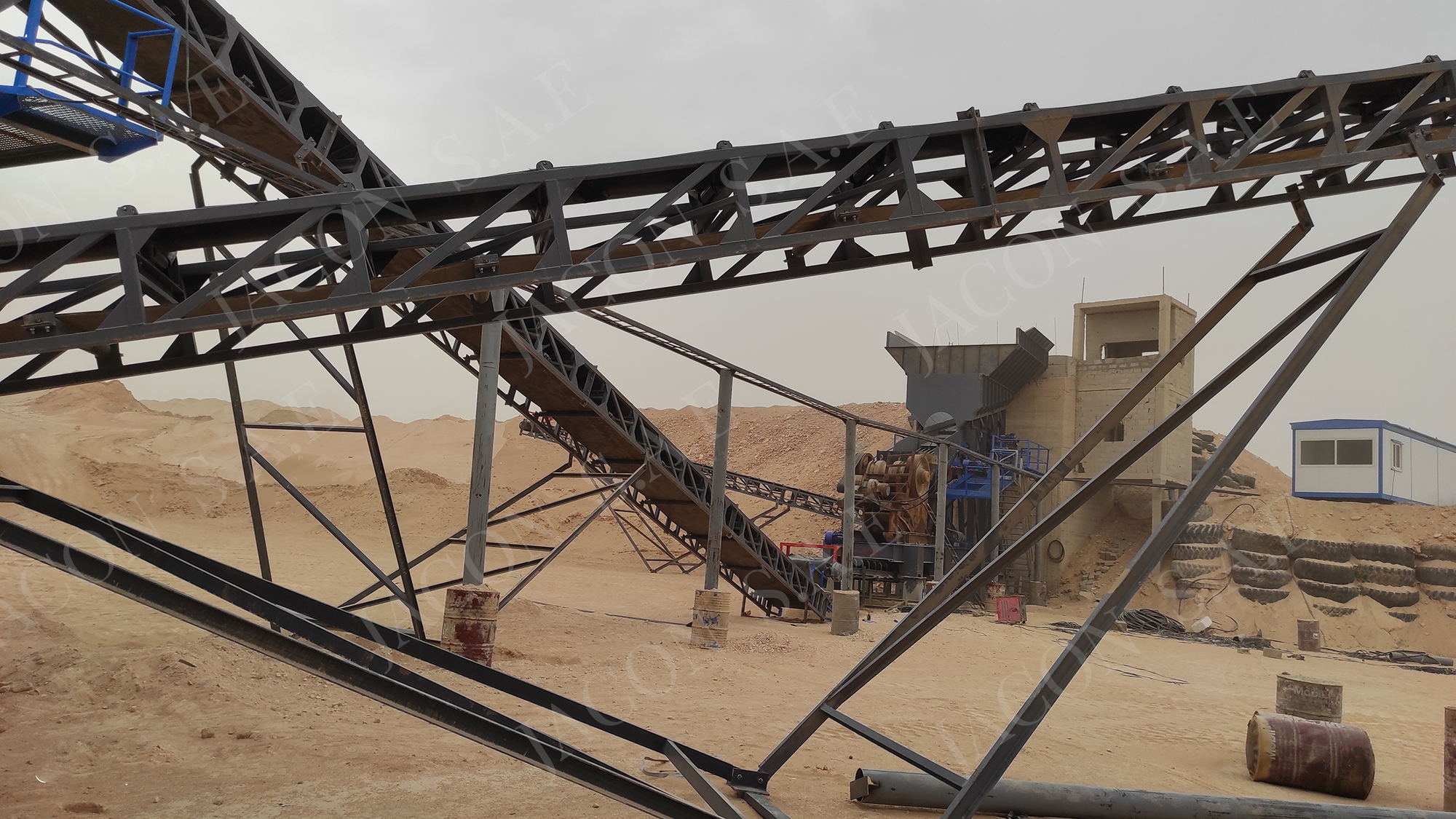

Crushers and crushing units

Crushers and crushing units Crushers are machines used to reduce the size of rocks, stones and aggregates. They are often used in aggregate production, recycling of building materials, and in mining operations. Our offer covers various cone crushers, jaw crushers, cone crushers, and impact crushers and is optimized to meet any needs to reduce the size.

crushers

Crushers are widely used as the primary stage to produce fine particles whose size is more than 50-100mm, they are categorized as jaw crushers, conical and cone crushers based on pressure, cutting mill based on shear crusher and hammer based on impact.

- crush jaw

It mainly consists of two crushing plates, tending to each other to form a horizontal opening of the lower boundary, where the material is crushed between the fixed and moving plate by reciprocating pressure until the crushed product is small enough to pass the gap between the crushing plates.

Jaw crushers find wide application for brittle materials for example, they are used to break up porous copper cake.

- axle crusher

The solid cone assembly includes a rotor shaft placed inside a hollow body, which has conical or vertical sloping sides, and then the materials are crushed when the crushing surfaces approach each other as the crushed products fall through the discharging hole.

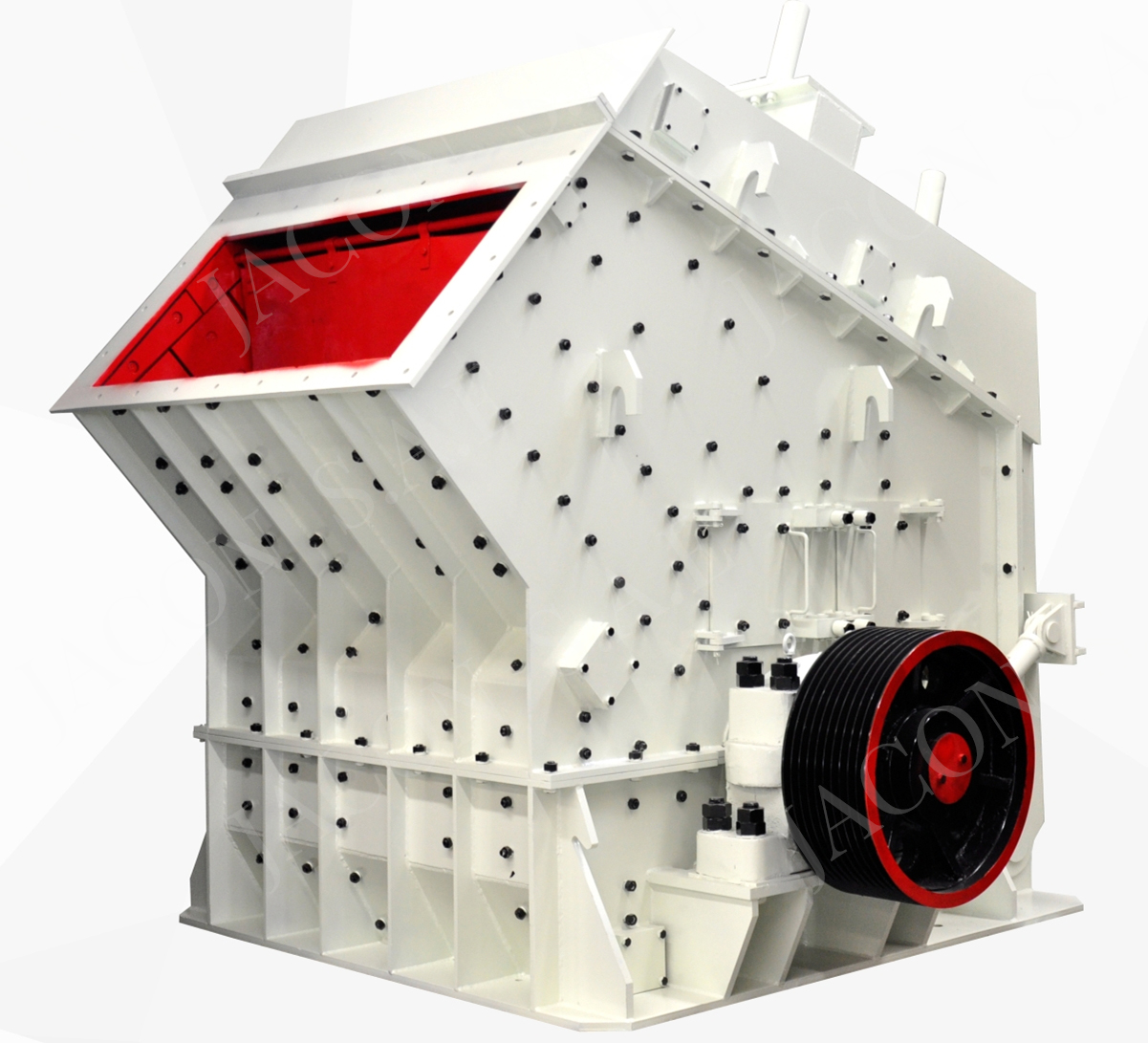

- hammer crushers

Hammer crushers use either a one-step primary crusher or a secondary crusher for products from a primary crusher. It is widely used to crush solid scrap metal for various hard metal recycling processes.

How do crushers and crushing units work

Axial hammers are suspended, mounted on symmetrical horizontal axes along the circumference of the rotor, and crushing is carried out by the impact of cutting materials with high-speed mobile hammers and by contacting the crushing plates.

A cylindrical mesh or strainer is placed under the rotor, where the material is reduced to a size small enough to pass the mesh or screen slots, the product size can be regulated by changing the spacing between the mesh bars or opening the screen.

The advantage of hammer crushers is the appearance of high air pressure in the discharge unit of the crusher and low pressure in the area around the shaft near the inner surface of the side walls of the structure.

Thus, hammer crushers also act as high pressure forced draft fans, this may lead to environmental pollution and product losses in fine powder fractions.

The design of the hammer crusher mainly allows to reduce the high pressure of air in the discharge unit of the crusher.

The main types of crushers are:

jaw crusher : The materials are crushed between a fixed jaw and a moving jaw, the feed is subjected to multiple pressures as it passes down as the size is gradually reduced until it becomes small enough to pass from the crushing chamber, as this crusher produces granules less in size but the aggregate is more elongated.

cadence crusher : Aggregates are produced by shock and therefore a higher fine content.

hammer crusher (impact) : The feed is fragmented by the kinetic energy introduced by the rotating mass (rotor) which drops the material on a fixed surface causing it to be shattered, further reducing the particle size, this crusher produces a more rounded shape.

circular or cone crusher: It uses a repeated compaction process with fixed and movable crushing members, this type of crusher produces less than 20% of fine flakes, and the aggregate is in cubic shape.

roller crusher: This breaker consists of two cylinders that rotate in opposite directions around two parallel axes.

rotary bottom crusher

The main manufacturing steps are as follows:

- Site selection and separation

- Weighting and control

- fragmentation

- primary crushing

- magnetic separation of steel

- Manual separation of plastic, wood and paper

- secondary crushing

- screening